Industries have been a part of our day to day activity since a long time and provides earning to a huge population across the world. Industries are directly impacting the life of workers so there are greater chances that we come across occupational risks that may cause irreversible effects on our workforce. Occupational Health & safety management system or OHSAS 18001 guidelines for industries are very helpful and aims toward safety of workers by planning risks. Compliance plays an important role in providing the direction for imposing stringent control over your process, in general. However, it is always up to organization what level of management controls they want to build. Productivity management Group is working as a pioneer OHSAS consultant and helping organizations build on OH&S practices.

Need of safety management system

Implementing OH&S MS 45001:2018 is the same for any industry in terms of what steps should be taken for effective implementation. A nicely built Occupational Health & safety policy will need to be written, and followed to achieve the intended outcome of the OHSAS. ISO 45001:2018 is helping us to integrate work safety with the strategic interest of the company. OH&S MS aims to cutting down cost to the company by planning the work safety. So, it’s like a win-win situation for both.

Structure of ISO 45001:2018

After the revision of previous OHSAS 18001 to ISO 45001:2018, ISO has clearly indicated its seriousness toward the safety of workers round the globe. Now, ISO 45001:2018 is based on Annexure SL i.e. High level structure.

- Scope of ISO 45001:2015

- Normative references

- Terms and definitions

- Context of the Organization

- Leadership and Worker Participation

- Planning for the OH&S System

- Support

- Operation

- Performance Evaluation

- Improvement

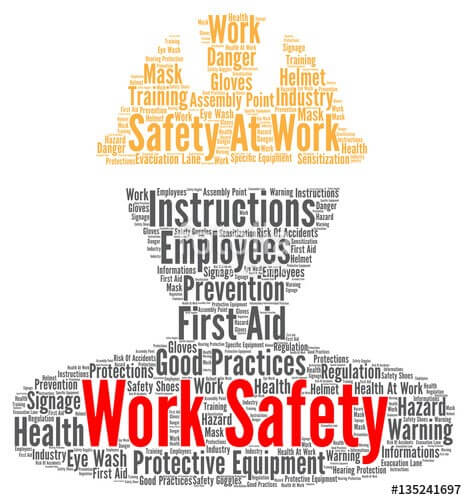

ISO 45001:2018 unlike others is based upon Plan-Do-Check-Act process approach

Compliances Identification & Management

To ensure safe working operation and avoid mishaps, government and other regulatory bodies have framed various compliances.

Some of the important legal & other requirements for environment protection are as follows:

- The Factories Act, 1948

- The Mines Act, 1952

- The Workmen Compensation Act, 1923

- The Dock workers (Safety, Health & Welfare) Act, 1986

- The BOCW Act, etc.

As per ISO 45001:2018, Occupational Health & safety Management System we need to identify what are requirements are applicable on us and how often do we need to evaluate. PMG has designed various integrated legal register that help organizations to manage their compliances in a better manner. Providing ESI and PF is not sufficient, law of the land has to be followed.

How OH&S MS be simplified and management steps

Step 1: Define Organization’s Goals for OH&S MS

The first step in OH&S MS planning is to decide why you are pursuing the development of an OH&S MS. Are you trying to improve your safety performance? Write your goals down and refer back to them frequently as you move forward.

Step 2: Secure Top Management Commitment

One of the most critical steps in the planning process is gaining top management’s commitment to support OH&S MS development and implementation. Management must first understand the benefits of an OH&S MS and what it will take to put an OH&S MS in place.

Step 3: Select An OH&S MS Champion

Not all small or medium-sized organizations have the luxury of choosing among multiple candidates, but your choice of project champion is critical. The champion should have the necessary authority, an understanding of the organization, and project management skills.

Step 4: Build an Implementation Team

A team with representatives from key management functions (such as engineering, finance, human resources, production and/or service) can identify and assess issues, opportunities, and existing processes. Include contractors, suppliers or other external parties as part of the project team, where appropriate.

Step 5: Hold Kick-Off Meeting

Once the team has been selected, hold a kick-off meeting to discuss the organization’s objectives in implementing an OH&S MS, the initial steps that need to be taken and the roles of team members.

Step 6: Conduct Preliminary Review

The next step is for the team to conduct a preliminary review of your current compliance and other safety programs/systems, and to compare these against the criteria for your OH&S MS (OHSAS 18001).

Step 7: Prepare Budget and Schedule

Based on the results of the preliminary review, prepare a project plan and budget. The plan should describe in detail what key actions are needed, who will be responsible, what resources are needed, and when the work will be completed. Keep the plan flexible, but set some stretch goals. Think about how you will maintain project focus and momentum over time

Step 8: Secure Resources, Assistance

The plan and budget should be reviewed and approved by top management. In some cases, there may be outside funding or other types of assistance that you can use (from a trade association, a state technical assistance office, etc.).

Step 9: Involve Employees

Ownership of the OH&S MS will be greatly enhanced by meaningful employee involvement in the OH&S MS development process. Employees are a great source of knowledge on health and safety issues related to their work areas as well as on the effectiveness of current processes and procedures.

Step 10: Monitor and Communicate Progress

As you build the OH&S MS, be sure to regularly monitor your progress against the goals and project plan, and communicate this progress within the organization. Be sure to communicate the accomplishments that have been made and describe what happens next. Build on small successes. Be sure to keep top management informed and engaged, especially if additional resources might be required.

PMG’s Factor

In PMG we have the best of the OH&SMS or OHSAS consultants which aims at developing the competence in the organization by making the employees do the work under the continuous guidance and gainful knowledge experience.

Bibliography:

Image Source: https://www.inc.com/gene-hammett/4-ways-you-can-and-should-simplify-your-sales-process.html