Impact of energy on your profits is not new. It is one of the foremost factor, to which most of the organization pay less attention. In any industry, the three top operating costs are often found to be energy (both electrical and thermal), labour and materials. Among the three, energy has the highest potential for cost reduction. So, if steps are not taken towards control on energy performance, now, the future of the businesses will be unfortunate.

World order is now being determined by energy

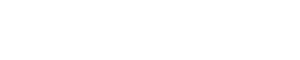

In today’s world, energy is quite critical a factor which drives every aspect of our surrounding. According to BP statistics, world oil and gas reserves are estimated to last for 53 years and 55 years respectively and coal to be for 113 years at current reserve/production ratio and still the demand for energy at global level is still increasing year after year.

World, witnessing a steady growth of energy demand, somehow, signifies that the availability of energy will be getting precariously scary, due to continuous depletion of natural resources. Countries need to prepare for the future by use of alternate renewable energy sources.

Industry need to specially focus on energy performance

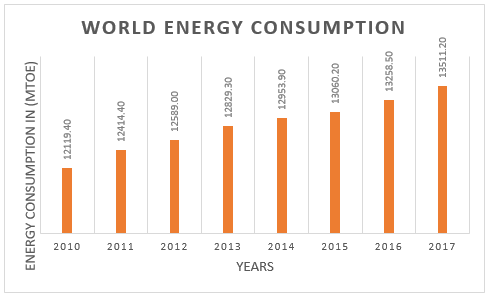

After automobiles, major energy consumption is in the manufacturing sector. Most of manufacturing industries consist of big furnaces, heavy machines, boilers, cooling towers, compressors etc. According to BP statistical review, India consumes 753.7 million tons of oil equivalent energy out of which coal consumption remains 56.30%, oil 29.46, natural gas 6.10% and renewable resources 2.89%.

It was pretty evident that about 85% of energy consumption in India is through coal and oil and both the commodities have 17.32 MT and 35.413 MT imports, respectively.

Therefore, India’s energy economics will continue to depend on international prices and currency rates. Being aware of India’s dependencies on imports, organizations will have no choice but to pay attention to improve energy performance and explore investments in renewable energy sources.

If organizations don’t wake up now, they will continue to bleed profits

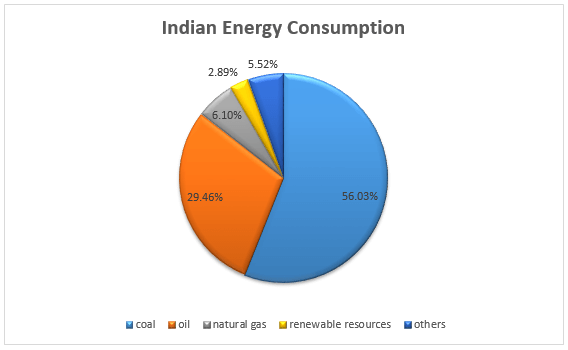

Sky rocketing prices of fuel, is going to present hardships for the industry. Competition has already exerted extra pressure for companies to be competitive. While the businesses would want to grow, but poor competitiveness will limit their abilities to position themselves at a level playing field.

Poor availability of skills and retention of existing skills will pose severe challenge to drive efficiency at all levels. Obsolescence of manufacturing technology, almost every decade, would require huge investments to be provisioned for the future. Such obsolete technologies will continue to consume high energy and the MSME’s would be badly hit by such an emerging scenario.

Thus it is incumbent on every manufacturing organization to consider their cost elements and drive efficiency, holistically, to ensure that specific cost consumption reduces. Organizations will remain valid, till they fight costs i.e., raw material cost, energy cost and labor costs by not only driving innovation but also productivity.

“Do you have high rated equipment, which were provisioned for large production parts but over a period of time, such equipment, continue to be dedicatedly used for small production parts. Is it ever considered from a renewed energy outlook?”

Energy performance will need a rethink and it needs to be carefully planned. The primary question is “How can organization be energy efficient?” Review the energy planning, re-consider energy needed vs energy consumed, consider alternate energy use(s) and explore renewable energy consumption. Least to say that high energy performance will be driven by high level of awareness, robust fitness of equipment and enhanced capacity utilization.

Creating Energy centric work culture will bring people, work with a mission

Organizations need to rethink and evolve a management system, which considers energy in daily affairs. Energy Management System (EnMS) of ISO 50001 could be positioned by the energy guzzling facilities in order to improve energy performance.

“It will be a great leap in business thinking to make energy centric work culture, in the organization.”

Have a re-look and consider the following low-cost measures, to improve energy performance:

- Planning of facilities

- Capacity utilization

- Augmenting maintenance practices

- Life cycle perspective

- Energy considered, purchases

- Capacity building of people, focused on energy efficiency, use & consumption

- Awareness Campaigns

- Energy management system of ISO 50001:2018

Think Risk

“Not knowing the risk can bleed the profitability”

Considering risk, helps an organization to manage possible impacts on energy in an efficient and effective way. Consider following risks and evolve the Energy management System.

- Poor planning

- Inadequate condition monitoring

- Insufficient maintenance practices

- Poor service performance by service providers

- Poor asset reliability

- Energy losses & leakages

- Poor skills and understanding of energy centric working

- Mis-informed decision making

Organization will be compelled to identify and prioritize the risk and opportunities in order to take effective action to address the strategic direction, which will lead to growth of the company’s energy performance, thereby increased profits.

Energy planning will remain critical to organization’s performance

Energy planning helps an organization to analyze its energy data, along with other energy information and is used to make informed decisions on actions to continually improve energy performance and productivity of an organization.

Some common scenario of planning, where energy should be considered

- Production planning

- Procurement of energy related products and services

- Maintenance planning

- Capacity utilization planning

And, if not considered:

- High energy costs

- Poor asset management plans

- Poor contingency planning

- Poor maintenance

- Wastage of energy

- Increased greenhouse gas emissions

- Compliance issues

Evolving energy management system, will provide a systematic approach for energy planning within an organization in following ways:

- Helps in identifying risks

- Provide a platform to conduct energy review and Energy baseline.

- Helps to drive objectives and targets related to energy.

- Helps in identifying relevant energy performance indicator.

- Action plan for achieving energy targets.

Thus, having a proper energy planning, will lead an organization to decreased energy costs and increased energy performance

There cannot be any shortcut to Legal compliances for saving energy.

“Complying with legal compliance is actually productivity as also safeguarding organization’s profitability”

Most of the organizations consider legal compliances as a hurdle but, not complying with legal compliances can lead to inefficient energy performance. Energy deployed for illumination could be costly, whereas a general illumination could have met the requirement.

Conclusion

The BIG picture suggests that energy centric work culture, energy planning, the risks and compliances can impact organizational profits and productivity. Complexities of energy scenario of the company can always be dealt, effectively by engaging partners who understand how to guide and coach energy managers of the company.

“Reducing carbon by adopting cleaner production techniques, will become the way of work.”

Employee engagement requires a very different skill set and to tap their creativity, brings another dimension. Organizations need to prepare themselves for the future of work. Industry needs to adopt, productivity enhancement techniques and become leaner, by the day.

To remain relevant and committed to Sustainable Development Goals (SDG’s) of United Nations, industry needs to contribute to make this world a better place.

Bibliography:

Image Source: https://zikua.tv/ru/article/ischeznovenie_lgotnogo_tarifa_na_elektroenergiyu_dlya_naseleniya_kakimi_budut_platezhki_za_svet_s_1_yanvarya_2021_goda_991464